.

.

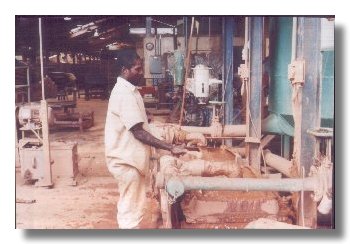

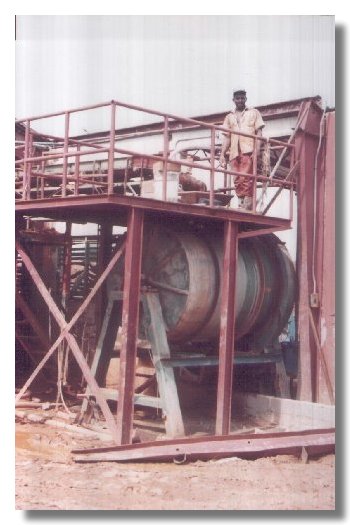

During the course of investigating the factory operations it was discovered that a fully serviceable ball mill was being used for dry grinding broken pottery for reintroduction into the ceramic mix. It was erroneously thought that this would in some way contribute to reducing the losses.

This ball mill was re-commissioned for the use of wet milling the 'problem' shale clay, the product then routed into the mixing and blending system. Accordingly all serious wear and tear on the mixers was eliminated.